Seasonal Crane Maintenance: Preparing for Winter in Monroe

KM

Understanding the Importance of Seasonal Crane Maintenance

As the cold season approaches in Monroe, ensuring that your cranes are in optimal condition becomes crucial. Winter can be particularly challenging for heavy machinery, and cranes are no exception. Regular maintenance not only enhances performance but also prolongs the lifespan of your equipment. As temperatures drop, it's essential to address specific maintenance tasks to avoid costly repairs or unexpected downtime.

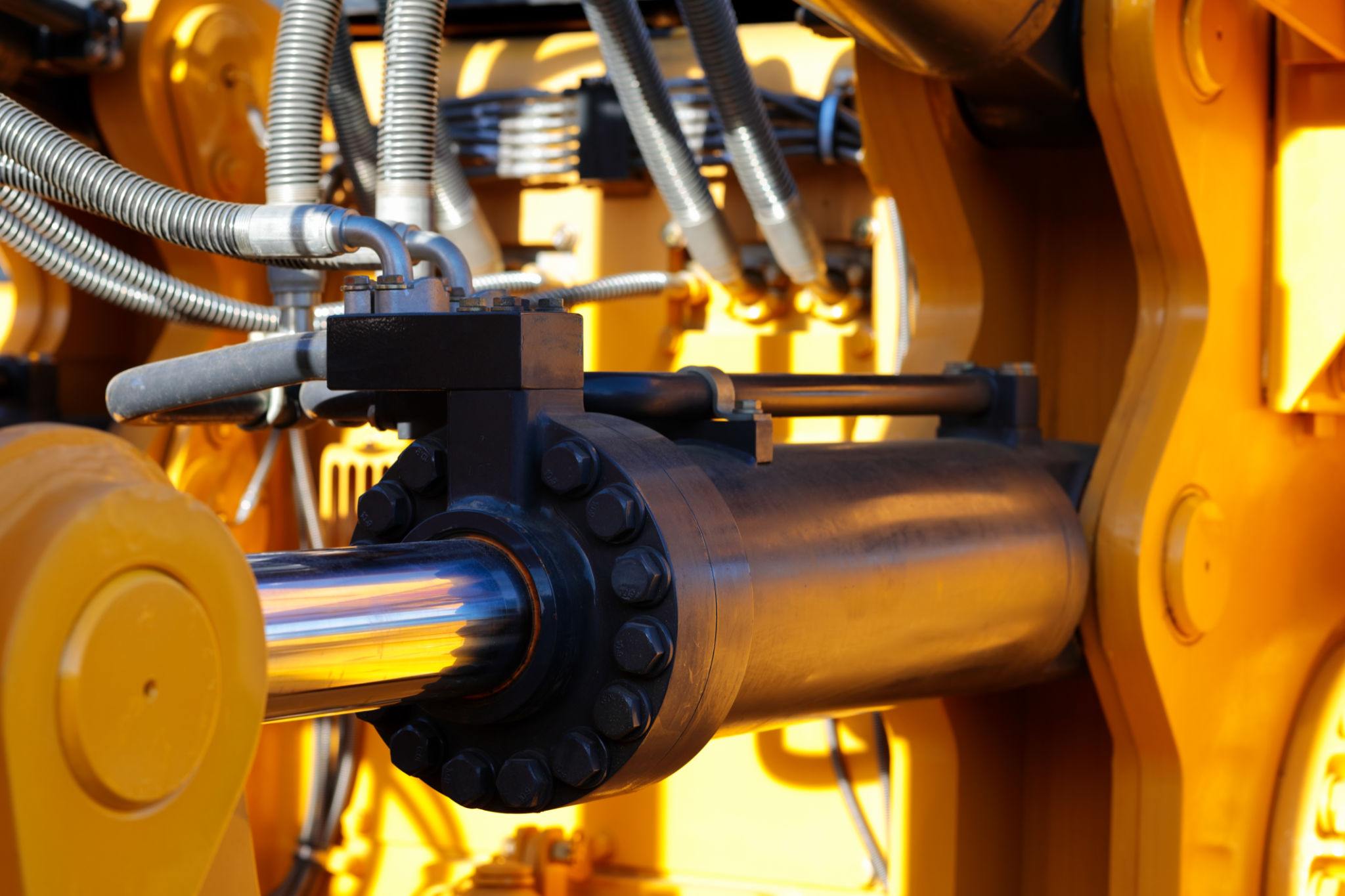

Inspecting the Hydraulic Systems

The hydraulic system is the heart of any crane, and maintaining it during the winter is vital. Cold weather can thicken hydraulic fluids, which may lead to reduced efficiency. It's recommended to use a winter-grade hydraulic oil to ensure smooth operation. Additionally, inspect hoses and seals for any signs of wear and tear, as these components can become brittle in low temperatures.

Regularly check and clean filters to prevent any blockages that could hinder performance. A thorough inspection will help identify potential issues before they escalate into significant problems.

Ensuring Proper Lubrication

Lubrication is another critical aspect of crane maintenance. In winter, standard lubricants may not perform adequately. Switching to a lubricant designed for low temperatures will help keep moving parts functioning smoothly. It's essential to apply these lubricants to all necessary components, including cables, pulleys, and joints.

- Use winter-grade lubricants.

- Regularly apply to all moving parts.

- Check for any signs of rust or corrosion.

Battery Health and Electrical Systems

Cold weather can significantly impact battery performance. Ensure that batteries are fully charged and in good condition before the onset of winter. Inspect connections for any corrosion and clean them as needed. It's also a good idea to have a backup battery available in case of emergencies.

The electrical systems should be thoroughly checked for any potential issues. Ensure that all lights are functional and that the control systems are responsive. Winter conditions often mean reduced visibility, making well-functioning lights essential for safe operations.

Protecting Cranes from Weather Elements

Exposure to harsh weather elements can accelerate wear and tear on cranes. If possible, store cranes indoors or use covers when they're not in operation. This practice will protect them from snow, ice, and moisture that can lead to rust and other damage.

- Store indoors whenever possible.

- Use protective covers.

- Regularly remove snow and ice build-up.

Creating a Winter Maintenance Schedule

To ensure nothing is overlooked, it's beneficial to create a comprehensive winter maintenance schedule. This schedule should include regular checks and servicing dates, ensuring that all aspects of crane maintenance are covered. Assigning specific tasks to team members can further streamline this process.

By following a well-structured maintenance plan, you can minimize the risk of unexpected breakdowns and enhance the safety and reliability of your cranes throughout the winter months in Monroe.